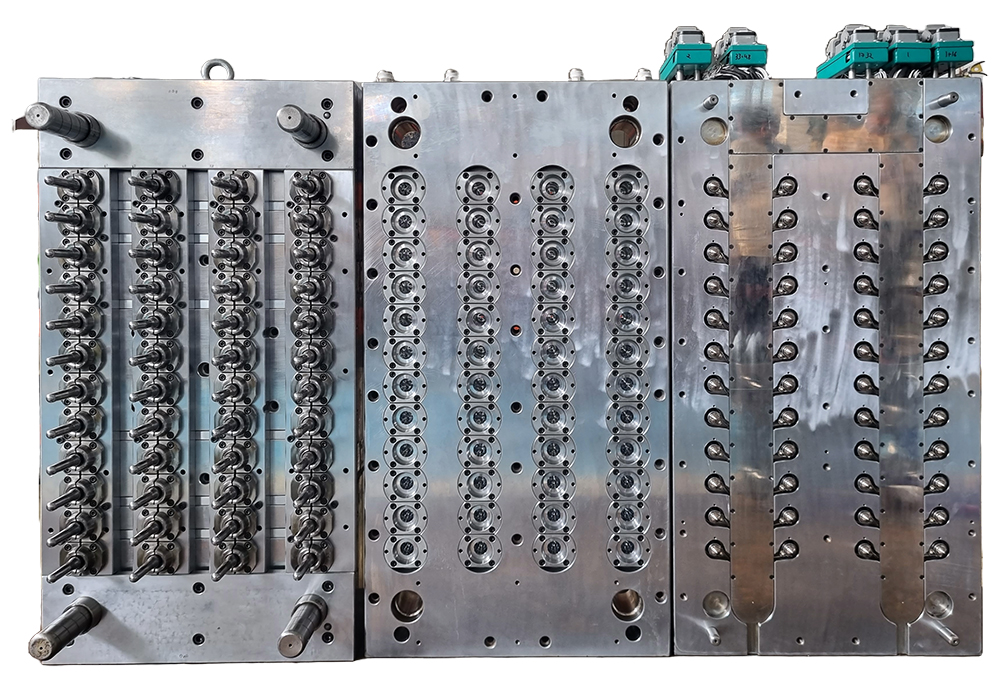

High-Precision PET Preform Moulds for Superior Packaging

At Ashish Tools, we specialize in high-performance PET preform moulds, engineered to deliver precision, durability, and efficiency. Our state-of-the-art manufacturing process ensures uniform preforms with superior surface quality, enabling seamless bottle production across multiple industries.

Why Choose Ashish Tools for PET Preform Moulds?

- Advanced Manufacturing – Designed for high efficiency with fast cycle times.

- Superior Quality – Our moulds are made with premium European steel for enhanced durability.

- Custom Solutions – Tailored preform designs to match diverse industry needs.

- Energy Efficient – Optimized for low acetaldehyde (AA) levels and minimal waste.

Our PET Preform Mould Capabilities

Ashish Tools offers a wide range of PET preform moulds with:

- Up to 72 cavities for high-volume production

- Preform weights from 6g to 760g

- Neck sizes from 12mm to 150mm

- Hot runner system with pneumatically controlled shut-off pin

- Interchangeable mould components for quick modifications

Industries We Serve

Our precision-engineered moulds cater to multiple industries:

- Beverages & Bottling – PET bottles for water, juices, and carbonated drinks.

- Cosmetics & Personal Care – Custom preforms for shampoo and skincare bottles.

- Pharmaceuticals – Secure packaging for medicinal and healthcare products.

- Food & Dairy – Airtight PET packaging for freshness.

- Household & Industrial – PET containers for cleaning and chemical products.

High-Performance Features of Our Moulds

- Minimal Eccentricity – Ensures perfect wall thickness uniformity.

- Hardened Steel Components – Extends mould lifespan and reduces maintenance.

- Surface Treatment & Coating – Allows smooth ejection of preforms.

- Roller Cams for Thread Splits – Precise opening and closing for perfect neck finish.

Reliable After-Sales Service & Support

Ashish Tools is more than just a PET preform mould manufacturer—we are your long-term partner. Our commitment to customer satisfaction includes:

- Mould commissioning & training at your factory.

- Stocked spare parts for quick replacements

- Expert technicians available for troubleshooting & maintenance.

Get the Best PET Preform Moulds from Ashish Tools

Upgrade your PET bottle production with high-precision, energy-efficient moulds from Ashish Tools. Contact us today to explore our custom solutions and achieve seamless, high-speed production.

Frequently Asked Questions

What is a PET Preform Mould? +

A PET preform mould is a specialized injection mould used to create preforms that are later blown into PET bottles. These moulds ensure consistent shape, weight, and durability.

How many cavities can a PET preform mould have? +

Our PET preform moulds range from 4 to 72 cavities, allowing high-speed production with minimal cycle time.

What industries use PET preform moulds? +

PET preform moulds are widely used in beverage, cosmetics, pharmaceutical, food, dairy, and household industries for bottle manufacturing.

How does Ashish Tools ensure mould quality? +

We use high-quality European steel, precision engineering, and strict quality control to ensure long-lasting and high-performance moulds.

Can PET preform moulds be customized? +

Yes! We offer custom preform designs, weight optimization, thread modifications, and neck finish adjustments to meet specific production needs.