Best Plastic Bottle Cap Mould Manufacturer, Suppliers & Providers

Are you searching for a Plastic Bottle Cap Mould Manufacturer that ensures precision, durability, and efficiency? Our company specializes in manufacturing high-quality PET plastic bottle cap moulds, designed to produce PET caps with different neck sizes to suit various industries.

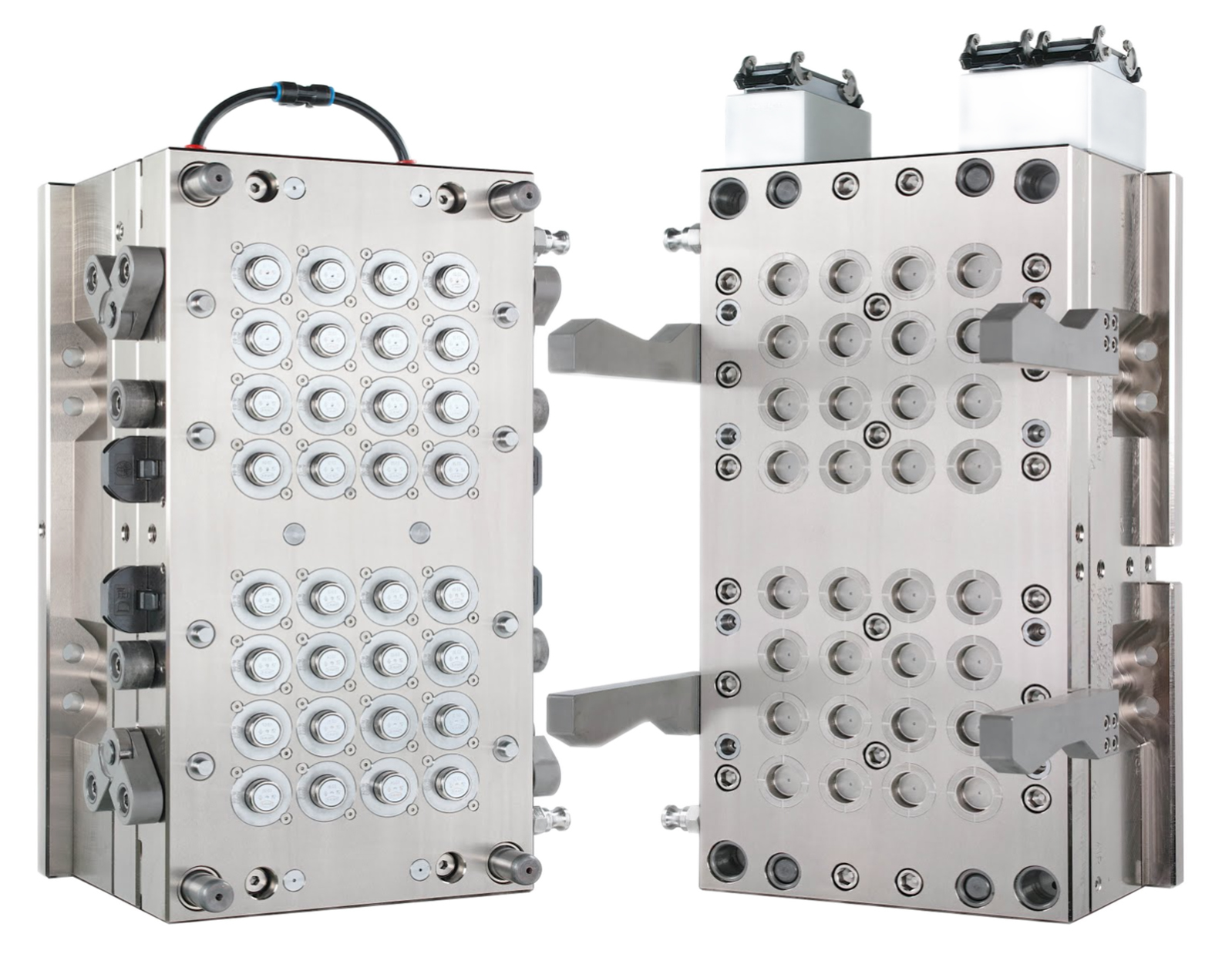

Advanced PET Plastic Bottle Cap Moulds for Superior Production

As a trusted Plastic Bottle Cap Mould Manufacturer, we provide state-of-the-art PET plastic bottle cap moulds capable of producing caps with neck sizes of 46 mm, 53 mm, 63 mm, 73 mm, 83 mm, and 96 mm. Our moulds use an advanced Stripper Ejection Process, where molten PET plastic is injected, shaped precisely, and seamlessly ejected. This process ensures high efficiency, reduced cycle times, and consistent quality in every cap produced.

Applications of PET Plastic Bottle Caps

Our PET bottle caps are widely used for sealing PET fridge bottles and PET jars, making them ideal for packaging a diverse range of products, such as:

- Roasted Snacks – Keeping them fresh and crispy.

- Cookies – Preserving taste, texture, and aroma.

- Spices – Maintaining aroma and quality with airtight sealing.

- Pickles – Preventing leakage while locking in flavors.

- Dry Fruits – Protecting against moisture and contamination.

- Nuts & Kernels – Ensuring long-lasting freshness.

- Chocolates – Preventing melting and spoilage.

- Berries – Extending shelf life while retaining natural taste.

With our high-quality PET plastic bottle cap moulds, manufacturers can produce leak-proof, durable, and well-fitted caps, maintaining product integrity across industries.

Why Choose Our Plastic Bottle Cap Moulds?

- Precision & Balance – Our moulds ensure perfectly shaped and balanced caps.

- Durability – Made from premium-grade materials, ensuring long-lasting performance.

- Shorter Cycle Times – Our optimized designs enhance production speed and efficiency.

- Machine Compatibility – Our plastic bottle cap moulds work seamlessly with all injection moulding machines.

- Leak-Proof & Secure Fit – Designed for tight, secure seals, preventing spills and contamination.

Comprehensive After-Sales Support & Service

As a leading Plastic Bottle Cap Mould Manufacturer, we provide dedicated after-sales support to ensure the long-term performance of your moulds.

- Technical Assistance – Our experts help with setup, troubleshooting, and optimization.

- Mould Maintenance Services – We offer refurbishment, repairs, and upgrades.

- Continuous Customer Support – Whether it's guidance on usage or quick servicing, our team is ready to help.

Why We Stand Out as a Plastic Bottle Cap Mould Manufacturer?

- Industry Expertise – Years of experience in plastic bottle cap mould manufacturing.

- Innovative Designs – Continuous improvements to meet industry demands.

- Customer-Centric Approach – Tailored solutions for specific business needs.

- High Production Efficiency – Designed for maximum output with minimal waste.

Get the Best Plastic Bottle Cap Moulds for Your Business

If you’re looking for a Plastic Bottle Cap Mould Manufacturer that offers high-performance, durable, and precision-engineered moulds, we are your ideal partner. Contact us today to discuss your requirements and boost your production!

Frequently Asked Questions

What cap sizes can your PET bottle cap moulds produce? +

Our moulds can manufacture caps in various sizes, including 46 mm, 53 mm, 63 mm, 73 mm, 83 mm, and 96 mm, making them suitable for PET fridge bottles and PET jars across multiple industries.

How does the Stripper Ejection Process improve moulding efficiency? +

The Stripper Ejection Process is an advanced moulding technique that ensures seamless cap removal, reducing cycle time and increasing production speed while maintaining high precision and consistent quality.

Which industries commonly use PET bottle cap moulds? +

Our PET bottle cap moulds cater to industries like food packaging, snacks, spices, pickles, dry fruits, chocolates, and beverages, ensuring airtight, leak-proof, and durable closures for better product preservation.

Do you offer after-sales support and mould maintenance? +

Yes! We provide comprehensive after-sales support, including technical assistance, mould refurbishment, repairs, and upgrades, ensuring long-term performance and high production efficiency.